Cement and concrete has existed for thousands of years. Find out which concrete type mixes existed in ancient times, key historic milestones in its development, how it developed to the ready-mix we use today and historic buildings created using concrete.

6500 BC – The first concrete-like structures were built by the Nabataea traders

The first concrete-like structures were built by the Nabataea traders, who occupied and controlled a series of oases and developed a small empire in the regions of southern Syria and northern Jordan.

5600 BC – Homes along the Danube River were built using a type of concrete for floors

By about 5600 BC, along the Danube River in the area of the former country of Yugoslavia, homes were built using a type of concrete for floors.

3000BC – The ancient Egyptians used mud mixed with straw to form bricks

Around 3000 BC, the ancient Egyptians used bricks formed from a mix of mud and straw, more similar to adobe than concrete. They also used gypsum and lime mortars when building the pyramids.

The Great Pyramid at Giza required tons of mortar, which was used as a bedding material for the casing stones that formed the visible surface of the finished pyramid.

3000BC – The Chinese used concrete for building boats and the Great Wall

The northern Chinese used a form of cement in boat-building and in building the Great Wall. For the Chinese, a key ingredient in the mortar used many of their structures was glutenous, sticky rice.

700BC – Nabataea discovered the advantages of hydraulic lime

Nabataea discovered the advantages of hydraulic lime – cement that hardens underwater. By 700 BC, they were building kilns to supply mortar for the construction of rubble-wall houses, concrete floors, and underground waterproof cisterns. These cisterns were kept secret and were one of the reasons the Nabataea were able to thrive in the desert.

600BC – The Greeks had discovered a natural pozzolan material

By 600 BC, the Greeks had discovered a natural pozzolan material that developed hydraulic properties when mixed with lime.

200BC – Romans were building very successfully using concrete

By 200 BC, the Romans were building very successfully using concrete, more like cemented rubble than a plastic flowing material poured into forms that we use today.

They built many of their structures by stacking stones of different sizes and filling the spaces between the stones with mortar. For cosmetic purposes, the walls were then clad with clay bricks that also served as forms for the concrete.

The mortars most commonly used were a simple limestone cement that hardened slowly after reacting with airborne CO2. True chemical hydration did not take place.

When infrastructure requiring more durability was required, the Romans made cement from a naturally reactive volcanic sand called harena fossicia. For structures exposed to water, such as bridges, docks, storm drains and aqueducts, they used a volcanic sand called pozzuolana.

The Romans also used these materials to build large structures, such as the Roman Baths, the Pantheon, and the Colosseum, and these structures still stand today.

125 AD – Rome’s Emperor Hadrian completes the Pantheon

The Pantheon has the largest unreinforced concrete dome ever built. 142 feet in diameter with a 27-foot hole, called an oculus, at its peak, which is 142 feet above the floor.

476 AD – The fall of the Roman Empire and concrete technology

After the fall of the Roman Empire in 476 AD, the techniques for making pozzolan cement were also lost, that was until the discovery in 1414 of manuscripts detailing those techniques.

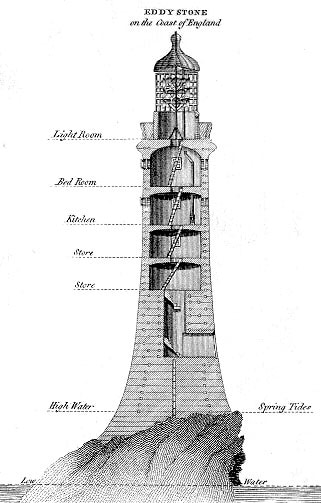

1793 AD – John Smeaton discovers a more modern method for producing hydraulic lime for cement

Technology took a big leap forward when John Smeaton discovered he could use limestone containing clay fired until it turned into clinker, which was then ground it into powder.

He used this material in the historic rebuilding of the Eddystone Lighthouse in Cornwall, England.

1824 AD – Joseph Aspdin invented Portland cement

An Englishman named Joseph Aspdin invented Portland cement by burning finely ground chalk and clay in a kiln until the CO2 was removed. He named it “Portland” cement because it resembled the high-quality building stones found in Portland, England.

Aspdin further refined his method by carefully proportioning limestone and clay, pulverizing them and then burning the mixture into clinker, which was then ground into finished cement.

1851 – The first home in England built using prefabricated concrete

Built in 1851 to resemble a Tudor gatehouse, Castle House, Bridgwater, England the construction uses panels of prefabricated concrete, with significant further usage of concrete throughout the building.

1875 – the first reinforced concrete home in the U.S

In 1875, American mechanical engineer, William Ward, completed the first reinforced concrete home in the U.S. It still stands in Port Chester, New York. It was built out of concrete because of his wife’s fear of fire.

1870s – Hennebique started building steel-reinforced homes in France

Hennebique started building steel-reinforced homes in France in the late 1870s and was highly successful, eventually building an empire by selling franchises in large cities.

1885 – The more efficient horizontal kiln developed

1885, an English engineer developed a more efficient kiln that was horizontal, slightly tilted, and could rotate. The rotary kiln provided better temperature control and did a better job of mixing materials. By 1890, rotary kilns dominated the market.

1887 – Ransome started building with steel-reinforced concrete

Ransome started building with steel-reinforced concrete in 1877 and patented a system that used twisted square rods to improve the bond between steel and concrete.

1891 – The first concrete street in the U.S

In 1891, George Bartholomew poured the first concrete street in the U.S., and it still exists today. The concrete used for this street tested at twice the strength of modern concrete used in residential construction.

1902 – Apartment building in Paris using steel-reinforced concrete

August Perret designed and built an apartment building in Paris using steel-reinforced concrete for the columns, beams and floor slabs. The building had an elegant façade, which helped make concrete more socially acceptable. The building was widely admired and helped further the popularity of reinforced-concrete buildings in the years that followed.

1904 – The Ingalls Building is built

The first concrete high-rise building was constructed in Cincinnati, standing at 16 stories or 210 feet tall.

1909 Thomas Edison received a patent for the first long kiln

In 1909, Thomas Edison received a patent for the first long kiln. This kiln, installed at the Edison Portland Cement Works in New Village, New Jersey, was 150 feet long. This was about 70 feet longer than the kilns in use at the time. Industrial kilns today may be as long as 500 feet.

1911 – Risorgimento Bridge was built in Rome

In 1911, the Risorgimento Bridge was built in Rome. It spans 328 feet.

1913 – Ready-mix concrete invented

In 1913, the first load of ready-mix was delivered in Baltimore, Maryland.

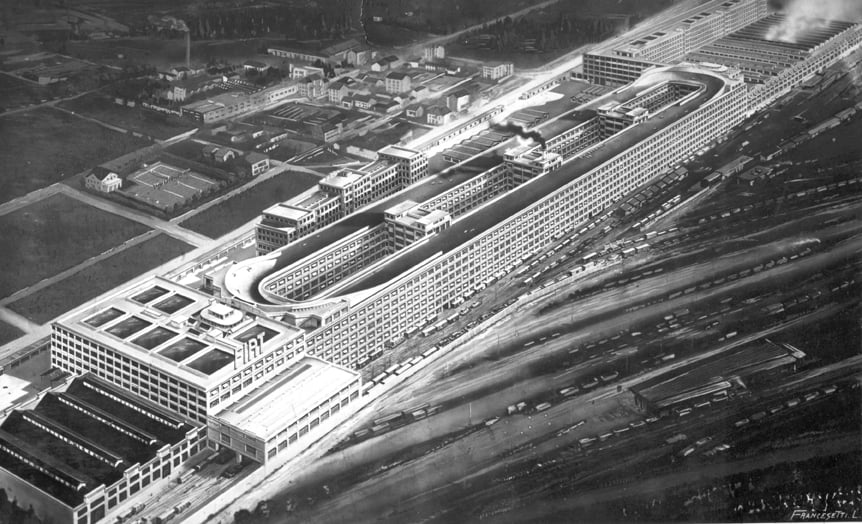

1915 – The five-story Fiat-Lingotti Autoworks in Turin

In 1915, Matte Trucco built the five-story Fiat-Lingotti Autoworks in Turin using reinforced concrete. The building had an automobile test track on the roof.

1935 – The Hoover Dam Built

In 1935, the Hoover Dam was completed

1942 Grand Coulee Dam was completed

The Grand Coulee Dam in Washington, completed in 1942, is the largest concrete structure ever built.

1962 – renewed interest in using reinforced concrete for high-rises

Construction in 1962 of Bertrand Goldberg’s 60-story Twin Towers, in Chicago, sparked renewed interest in using reinforced concrete for high-rises.

1963 – The Assembly Hall at the University of Illinois is built

The amazing concrete dome is considered an engineering marvel, because concrete contractors used prestressed concrete in a way it had never been used before.

Concrete contractors built the 128 feet high hall, with a dome spanning 400 feet of ribbed reinforced concrete.

2010 – The Burj Khalifa built in Dubai

The world’s tallest structure was built using reinforced concrete. The Burj Khalifa in Dubai in the United Arab Emirates (UAE), stands 2,717 feet tall.